打开微信扫一扫

打开微信扫一扫MZ-E系列悬挂式单丝埋弧焊接系统

MZ-E series suspended single wire submerged arc welding system

产品特点

1、逆变电源技术使得焊接电流更加稳定,可以提供更高的电弧稳定性和电极焊接效率。

2、逆变电源能够提供同等功率下出色的电气性能,也因此使用更少的电能。

3、由于其专业化生产悬挂设备的设计,可以采用高功率电极在快速焊接时达到较高的熔敷金属速率。

Product Features

1. Inverter power technology makes welding current more stable, providing higher arc stability and electrode welding efficiency.

2. Inverter power supply can provide excellent electrical performance at the same power, thus using less electricity.

3. Due to its specialized production suspension equipment design, high-power electrodes can be used to achieve high deposition metal rates during rapid welding.

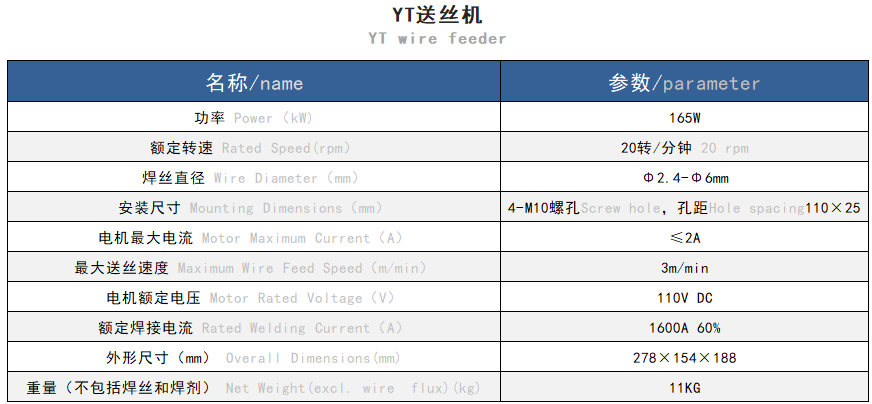

技术参数/Technical Parameter